Mining

The main component of cemented carbide comes from tungsten We

have our own mines, We start from mining to ensure the quality and

supply Of raw materials. We control and ensure the product quality from

the powder source.

Powder Preparation

Tungsten ore evolved into tungsten carbide through smelting process. and finally prepared RTP powder, In recent 30 years, the company has developed and accumulated smelting technology. Our Company has comprehensive grades covering almost all the machining applications, and even the nano grade with tungsten carbide grain as fine as 0.2 um for hard machining.

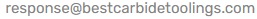

Pressing

RTP powder is made into green part by pressing process. We have three ways of pressing blanks,traditional cold pressing. cold isostatic pressing and extrusion. AS well, we possess the ability Of soft shaping to reach net-shape products.

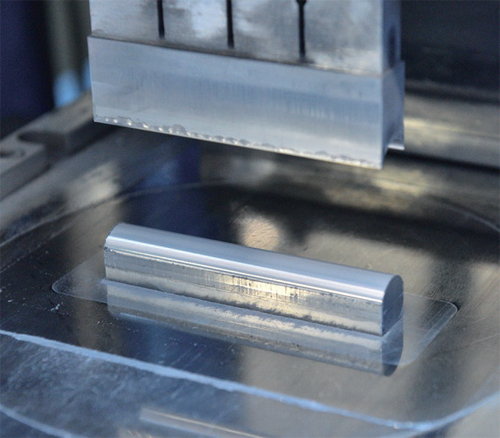

Sintering

After sintering of high temperature, the green cemented carbide with high hardness. Achteck has the most advanced sinterhg «lupments and match the unique sintering to ensure the compactness and uniformity of the microstructure after sintering.

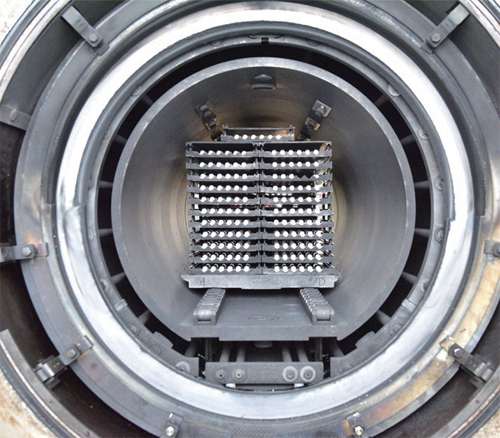

Grinding

According to different applications and customer requirements, cemented carbide products need to go through finishing processes such as grinding to meet the required Size and accuracy. We always contrd the grinding accuracy with more tight tderance.

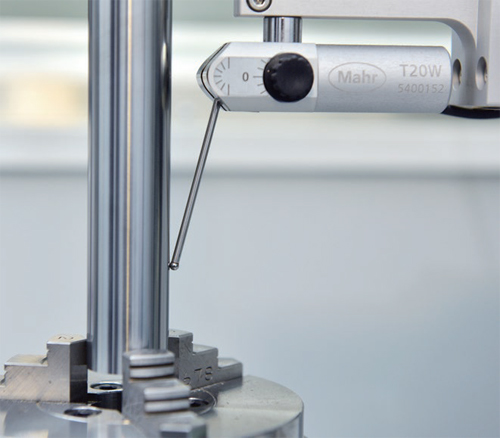

Quality Control

Any minor defect may seriously affect the performance Of carbide products. The advantages of possessing a complete industrial chain enable us to strictly control the quality of all the production process, which to maintain the stability and of product performance.